Should Cost for a 20 kVA dry-type electrical transformer

Published by Pasquale Marzano. .

Electrical Appliances Should Cost

In light of the energy transition process, some technologically advanced products, such as EV car batteries and electrical transformers, are taking on an increasingly important role.

In this article the should cost methodology is applied to electrical transformers, following the scheme used in the article relating to lithium ion batteries NMC 1-1-1.

What are electrical transformers

Transformers are electromagnetic devices used to change the voltage levels of an electrical circuit. They include a very high variety of devices: from the large oil transformer with a power exceeding 10 thousand kilovoltamperes (kVA), necessary to reduce the voltage from the electrical transport networks to the distribution ones; to the small dry transformer with a power of less than 1 kVA, used in LED drivers to reduce the 220 volt voltage of domestic systems to the few units of volts necessary for the optimal functioning of the LEDs themselves.< br>

They are generally distinguished by cooling mode. In oil transformers, cooling occurs by immersing the transformer in an electrical insulation oil (dielectric oil) and dispersing the heat via a radiator. In dry-type transformers, cooling occurs through air and possibly through a fan.

Excluding the cooling mode, transformers are composed of the following main components:

- two windings of wire typically made of copper or aluminum: a primary current input and a secondary output;

- a magnetic core made of magnetic sheet metal that guides the magnetic flux from the primary winding to the secondary winding;

- a case, made of rigid materials such as steel, aluminum alloys, or other metals; or epoxy resins or other thermosetting materials;

- insulators and connectors to electrically isolate the winding terminals and to connect the transformer to the external electrical system.

Transformers often also have control systems made of temperature sensors and protective devices such as circuit breakers or fuses. Oil-filled transformers may have pressure valves and oil level indicators.

Construction of the Should Cost of an electrical transformer

The following describes the construction of the should cost for a 20 kVA ventilated transformer used on board machine tools to reduce the voltage from 400 volts to 220 volts. This product is a dry transformer with a steel case, and is shaped to allow natural ventilation.

Cost Breakdown Analysis

The main materials that make up this type of transformers are shown in the following table:

Table 1: Cost breakdown of material costs for electrical transformer

| Material | Weight in kg per 1 kg of transformer | Cost driver | Cost driver price January 2022 (Euro/kg) | Material price January 2022 (Euro/kg) | % cost on total material costs |

|---|---|---|---|---|---|

| Copper | 0.25 | Copper wire (cross-sectional dimension of > 6 mm) | 8.84 | 2.21 | 69.5 |

| Cold-rolled electrical steel | 0.60 | Cold-rolled electrical steel N.G.O. (width ≥ 600mm) | 1.34 | 0.81 | 25.5 |

| Coils | 0.15 | Cold-rolled coils (thickness of 1-3 mm) | 1.09 | 0.16 | 5.0 |

| Total | 1.00 | 3.18 | 100.0 |

Since the price of a transformer of this type in January 2022 was close to 8 euros per kg, it is reasonable to assume a cost breakdown between materials and other costs (including actual and notional services and profit margins) equal to 40% and 60%.

Within the other costs, the cost of labor is generally equal to 5 times the cost of energy, which includes not only the energy component used in the production process, but also the fuel for transportation and the company's energy expenses.

The following table shows the percentages of the different costs that were used to calculate the should cost of this type of dry transformer.

Table 2: Cost breakdown of electrical transformer

| Material | Cost impact (%) | Cost driver |

|---|---|---|

| Copper | 27.8 | Copper wire (cross-sectional dimension of > 6 mm) |

| Cold-rolled electrical steel | 10.2 | Cold-rolled electrical steel N.G.O. (width ≥ 600mm) |

| Coils | 2.0 | Cold-rolled coils (thickness of 1-3 mm) |

| Energy | 10.0 | Total Energy Index (Europe) |

| Services and Labour | 50.0 | Consumer price index Euro Area |

| Total | 100.0 |

Should Cost

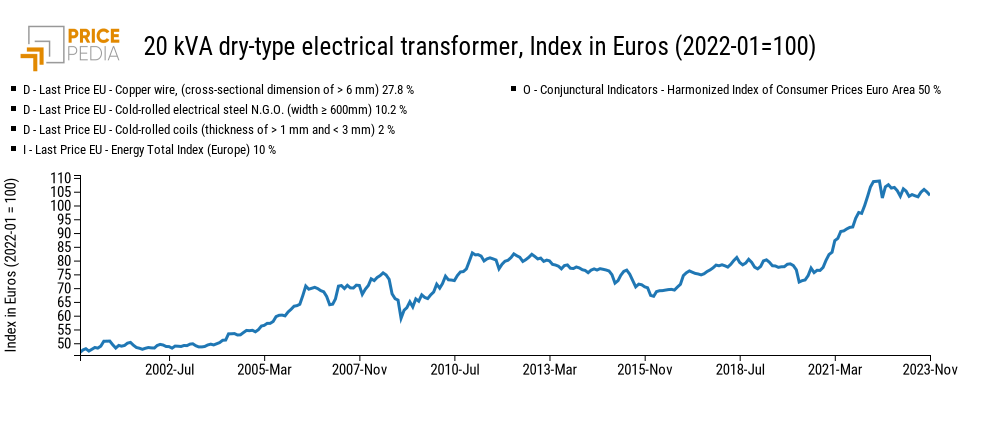

The dynamics of the should cost relating to the transformer considered is shown in the following graph.

Graph 1: Should cost of a 20 kVA dry-type electrical transformer

The graph allows us to highlight the sudden growth in the price of the electrical transformer starting from 2021, which culminated in the maximum point of the second quarter of 2022. Furthermore, this growth has no equal in the history of the last 23 years.

For over a year the levels have fluctuated around values just below the historic highs: on average in 2023, in fact, the price of the electrical transformer fell by only 1.5% compared to the average values in 2022.

Conclusions

In this article the should cost of a 20 kVA ventilated electrical transformer was constructed, considering both material costs and non-material costs. The analysis highlighted a strong growth in the price of electrical transformers in the two-year period 2021-2022 never experienced before. In the most recent phase, prices remain high, just below the maximum values of 2022.

Pasquale MarzanoEconomist and data scientist. At PricePedia he deals with the analysis of commodity markets, forecasting models for raw material prices and management of reference databases.