The United States at the Center of the Global Ethanol Market

From Brazil to Europe: How Ethanol Became the Key Additive in Unleaded Gasoline

Published by Luigi Bidoia. .

Biofuels Bio-Based Chemicals Price Drivers

With annual production exceeding 100 million tons, ethanol (or ethyl alcohol) is now one of the main bio-based chemical intermediates worldwide, alongside glucose derived from starch.

Ethanol can be produced through two different processes.

The first is the fermentation of sugars by yeast, the same biological process used to produce wine and other alcoholic beverages.

This method has been industrialized to generate large volumes of ethanol from biomass such as sugarcane and corn.

The second process is chemical synthesis through the catalytic hydration of ethylene.

Over time, the relative weight of these two processes has shifted significantly.

In the EU, for instance, ethanol production from ethylene remained dominant until the early 2000s, after which it was progressively replaced by fermentation-based industrial production, which has become the leading method in recent years.

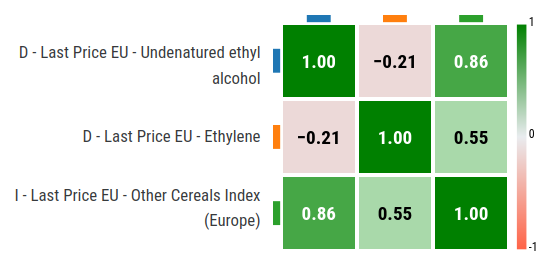

This transition is clearly reflected in the evolution of correlations between the prices of ethanol, ethylene and cereals other than soybeans and wheat.

The two figures that follow show the values of partial correlations — used to isolate direct effects — among these prices in the periods 2000-2010 and 2015-2025.

In the first period, ethanol prices show a significant correlation with ethylene prices, while no statistical correlation emerges with cereal prices.

In contrast, in the second period, ethanol prices are positively and significantly correlated only with cereal prices, indicating that fermentation has become the dominant production process.

Partial correlation between ethanol prices and the prices of its possible inputs

| 2000-2010 | 2015-2025 |

|---|---|

|

|

Globally, the development of ethanol has accelerated sharply, driven by its use as an essential component in oxygenated gasoline, making it a key additive in the energy and environmental policies of many countries.

The Development of Oxygenated Gasoline

The evolution of oxygenated gasoline began in the 1970s, when ethanol emerged as an alternative to lead-based additives, which were by then recognized as highly toxic. Thanks to its high octane rating, ethanol quickly became the natural candidate for improving the quality of unleaded gasoline. In Brazil, during the 1973 energy crisis, the government launched the Pró-Álcool program (1975), which initiated large-scale industrial production of ethanol from sugarcane and introduced widespread gasoline–ethanol blends. This marked the first structured application of oxygenated gasoline.

In the United States, from the 1980s and even more significantly during the 1990s, the Brazilian model evolved into a mature industrial ecosystem: ethanol produced from corn was initially adopted to comply with new environmental regulations and later, with the introduction of the Renewable Fuel Standard in 2005, became the cornerstone of a consolidated market for E10 and E85 fuels. In Europe, the spread of ethanol developed from the 1990s onward as the “second phase” of clean gasoline. Following the phase-out of lead, the gradual introduction of E5 and later E10 blends solidified the role of ethanol — either directly or via ETBE[1] — as an essential additive to increase octane levels, improve combustion, and contribute to renewable energy targets.

Ethanol Regulations

Because ethyl alcohol can be used to produce alcoholic beverages — which in most developed countries are subject to high excise taxes aimed at limiting consumption — governments have had to address a twofold issue.

On the one hand, they needed to prevent the abundant availability of ethanol from resulting in low-cost alcoholic beverages.

On the other hand, they sought to avoid the emergence of a parallel industry producing ethanol-based fuels designed to circumvent tax regimes.

The solution adopted by most countries has been to establish two distinct administrative frameworks: a highly regulated one for pure (or undenatured) ethanol, and a much less restrictive one for denatured ethanol, which is chemically modified so that it cannot be used in the production of alcoholic beverages.

The absolute leader in the global market for denatured ethanol is the United States, where the denaturing process is carried out directly at the source, in the same industrial facilities where fermentation-based ethanol is produced. Most of the ethanol sold on the U.S. market is indeed denatured, as this avoids the administrative and logistical costs associated with handling pure undenatured ethanol.

Fuel Ethanol

The widespread use of denatured fermentation-based ethanol as an additive in oxygenated gasoline led the U.S. industry to establish a commercial standard — Fuel ethanol — specifically designed for this purpose. Over time, this standard has become a key benchmark for the global ethanol market.

The chart below compares the FOB price of denatured ethanol exported from the United States (Fuel ethanol) with the price of denatured ethanol traded within the EU.

Comparison between FOB US denatured ethanol prices and Intra-EU customs prices

The relationship between the two price series is strong, even though significant short-term differences may occur. These divergences are largely explained by the different dynamics of raw material prices used in fermentation-based ethanol production in the two markets.

Conclusions

Among bio-based chemical intermediates, ethanol shares with glucose the position of the most important product in terms of global production and trade. Over the course of this century, ethanol has experienced substantial growth, driven by its use as an additive in the production of oxygenated gasoline. The country that has recorded the strongest expansion is the United States, where ethanol production absorbs around 40% of domestic corn output, making it a crucial market for American farmers. In the United States, ethanol production intended for oxygenated gasoline has led to the creation of a commercial standard that has become the international reference for ethanol prices in other producing regions.

[1] ETBE (ethyl tert-butyl ether) is a fuel additive obtained from the reaction between ethanol and isobutylene. Like ethanol, it is used to increase the octane rating of gasoline.