Engineered wood panels: comparison of characteristics and price levels

Published by Pasquale Marzano. .

Engineered wood Price DriversEngineered wood panels represent an extremely versatile solution, able to meet different needs in the furniture, construction, and various industrial sectors.

The different types are distinguished according to the required properties, such as lightness, mechanical strength, or moisture resistance. A first distinction can be made by considering their composition.

In particular, they can be divided into:

- Particleboard: made from pressed wood chips bonded with resins, they are the most economical and widespread solution in medium- and low-range furniture.

- Oriented Strand Board (OSB): composed of large, oriented and layered wood flakes, they combine mechanical strength and low cost, widely used in construction.

- Fiberboard (LDF, MDF, HDF): obtained from very fine wood fibers pressed at high temperature. The different density determines their properties and uses, ranging from furniture and interior design (MDF) to lightweight structural applications (HDF).

- Standard plywood: made of thin sheets of wood (veneers) glued together with alternating grain orientation, providing high stability and strength.

- Blockboard: consisting of layers of solid wood strips arranged perpendicularly, used in quality furniture and furnishings thanks to its strength and good workability.

- Laminated wood (glulam): composed of solid wood strips glued parallel to each other. Mainly used in structural construction as an alternative to solid wood, due to its strength and reliability.

- Plywood with blockboard or laminated core: a multilayer panel with a central core made of solid wood strips, which increases rigidity and stability, making it ideal for furniture and large surfaces.

Although the prices of the various panels also depend on aesthetic factors, such as the presence of decorative veneers in valuable wood species, the main cost drivers remain mechanical strength and lightness, elements that define their performance in different applications.

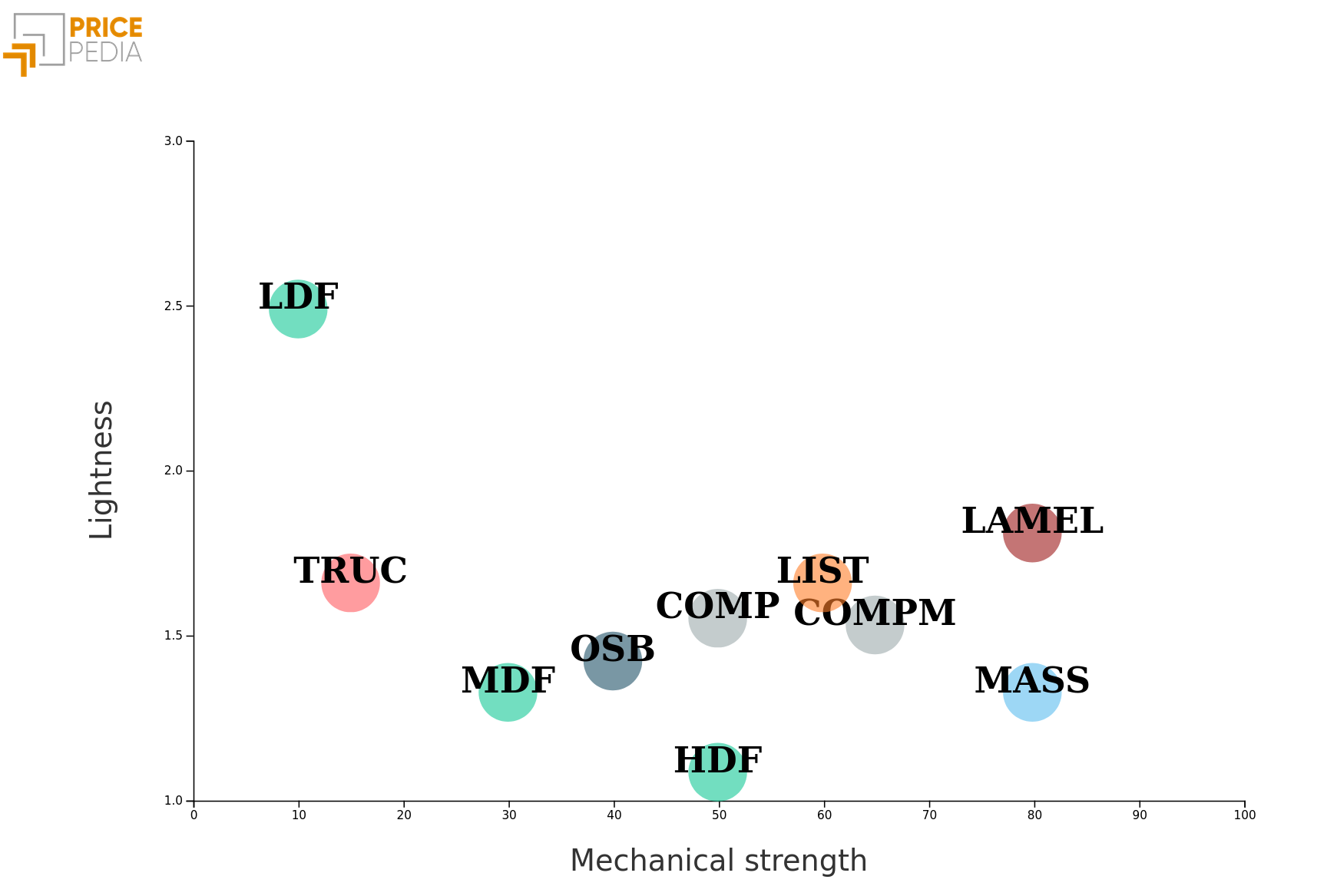

The following chart shows the different types of engineered wood panels based on these characteristics (lightness is measured as the inverse of average density multiplied by one thousand).

Characteristics of Engineered Wood Panels

The chart highlights how, even within the same family of panels, characteristics can vary significantly.

For example, among fiberboard panels, LDFs are extremely light but have very low strength, even lower than particleboard (TRUC). In contrast, MDF and HDF offer higher strength and quality, though at the expense of lightness.

A higher level of strength is found in standard plywood (COMP) and in plywood with blockboard or laminated core (COMPM), which combine robustness with good versatility.

Finally, laminated wood (LAMEL) reaches strength values comparable to solid wood (MASS), but with the advantage of being lighter, a feature that makes it particularly valued in construction.

Do you want to stay up-to-date on commodity market trends?

Sign up for PricePedia newsletter: it's free!

An initial confirmation of the importance of the technical characteristics shown in the chart comes from the analysis of the average prices of the different panels.

The table below shows the average values, expressed in euros per ton, of the main engineered wood panels.

Engineered Wood Panels: Average Annual Prices 2022–2025 (in Euro/Ton)

| 2022 | 2023 | 2024 | 2025 | |

|---|---|---|---|---|

| D-Last Price EU-Unworked particle board | 413 | 350 | 286 | 281 |

| D-Last Price EU-OSB | 605 | 459 | 437 | 468 |

| D-Last Price EU-MDF (thick. > 9 mm) | 576 | 528 | 440 | 441 |

| D-Last Price EU-Coated HDF panels (thickness > 9 mm) | 971 | 1049 | 917 | 886 |

| D-Last Price EU-Hardwood plywood | 1424 | 1608 | 1416 | 1426 |

| D-Last Price EU-Blockboard laminboard and battenboard (outer plies of hardwood) | 1715 | 1652 | 1504 | 1534 |

| D-Last Price EU-Laminated wood (external layers of hardwood) | 2274 | 2473 | 2410 | 2391 |

As shown by the characteristics above, Unworked particleboard panels are those with the lowest price level. OSB and MDF panels, on the other hand, show similar quotations. Staying within the fiberboard family, HDF panels show a higher price than MDF: in addition to the better properties of HDF, this differential can also be explained by the fact that HDF is often marketed with a surface coating.

As for the different types of plywood, their prices are generally higher than those of other panels, except for laminated wood, which exceeds 2000 euros per ton.